Mold & Die Production

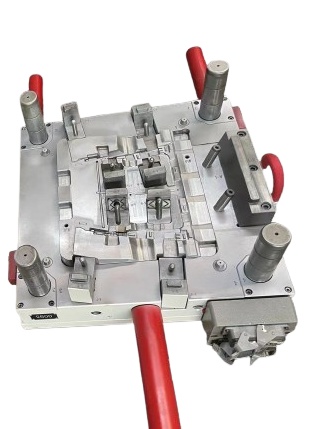

Customized Production Tooling

At SIX SIGMA, we specialize in providing unique tooling solutions for customers with low volume requirements. Our team of skilled engineers and skilled workforce, combined with state-of-the-art machinery, allow us to deliver high-quality tooling solutions with a fast turnaround.

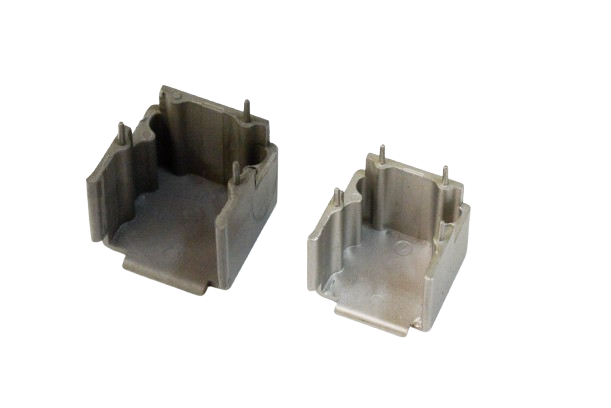

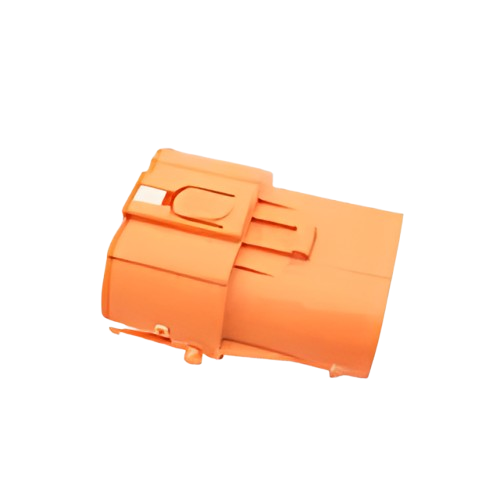

We offer mold making services for a wide range of plastic and metal products, and we can customize packaging and surface treatments to meet your specific needs. Whether you are looking for a one-time solution or ongoing support, we are here to help.

Contact us today to learn more about our low-volume tooling solutions and how we can support your business.

From A CAD File to the Finished Part

We are dedicated to supporting our customers every step of the way, from concept to design, production, and delivery. Our team of experienced toolmakers and state-of-the-art machinery allow us to accommodate both low-volume and high-volume production.

We utilize advanced Computer-Aided Design (CAD) software, including UG and Pro-e, to optimize your design and ensure that your products meet your exact specifications. Our completely in-house service allows us to expedite your project and get it to market in the shortest amount of time and with minimal cost.

We are proud to offer a comprehensive range of services that are designed to help your business succeed.

Design for Manufacturability (DFM)

We welcome the early involvement of our customers in part and mold design using Design for Manufacturability (DFM) Review which is the key to successful part and product development.

At Six Sigma, we emphasize the benefits of DFM to our clients with the knowledge that this powerful diagnostic tool will anticipate problems, find solutions, and reduce risks, create a more efficient production cycle.

Your molds are made with high-quality P20, Nak80, 738H, H13, S136 steels. We use multi-axis CNC mills, grinders, and EDM machines to create complex geometries with multiple surface finishes, from the highest optical polishes to matte and everything in between.